play a pivotal role in various industries, ensuring precision and reliability in fluid and gas systems. In this blog, we will explore the significance of instrumentation tube fittings and how they contribute to industrial efficiency. Additionally, we will shed light on two crucial elements in industrial processes—tungsten carbide powder manufacturing and tungsten powder supply.

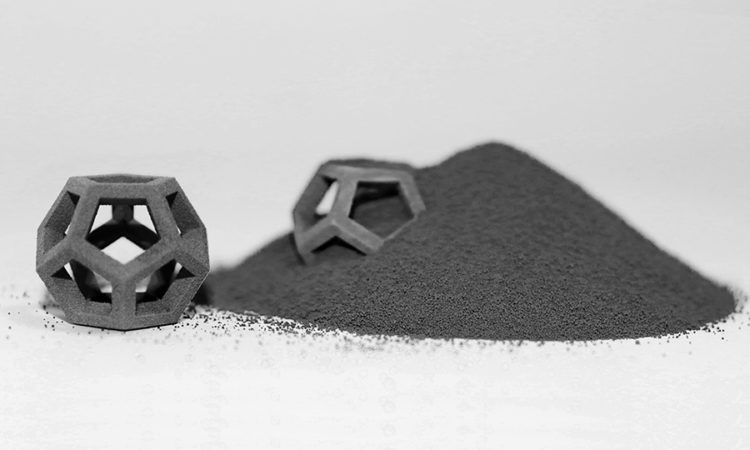

Understanding tungsten carbide powder:

tungsten carbide powder are essential to connect and secure tubes in fluid and gas systems. These fittings are designed to withstand high pressures and temperatures, providing a leak-free and durable solution for critical applications. Industries such as petrochemical, pharmaceutical, and aerospace rely on tungsten carbide powder to maintain the integrity of their processes.

Benefits of tungsten carbide powder india:

- Precision and Reliability: tungsten carbide powder ensure a tight and secure connection, minimizing the risk of leaks or system failures. This precision is crucial in industries where accuracy is paramount.

- Versatility: These fittings come in various materials, sizes, and configurations, making them adaptable to various applications. Stainless steel, brass, and other corrosion-resistant materials are commonly used, ensuring longevity and performance.

- Ease of Installation: Instrumentation tube fittings are designed for easy installation and maintenance. Their simple yet effective design allows for quick assembly and disassembly, reducing downtime in industrial processes.

Tungsten Carbide Powder Manufacturing:

Tungsten carbide is a key material in producing cutting tools, wear-resistant parts, and industrial components. use tungsten carbide powder manufacturer as a base material for producing high-performance tools and components. The hardness and durability of tungsten carbide make it ideal for applications where wear resistance is critical.

Tungsten Powder Supply:

Tungsten powder is a fundamental raw material in various industries, including aerospace, electronics, and metallurgy. tungsten powder supplier play a crucial role in ensuring a steady and reliable source of tungsten powder for manufacturing processes. The quality of tungsten powder directly impacts the performance and characteristics of the end products.

Conclusion:

tungsten carbide powder are the unsung heroes of industrial processes, providing the necessary connections for fluid and gas systems. Understanding their importance is key to maintaining operational efficiency and safety in various industries. Additionally, the roles of tungsten carbide powder manufacturers and suppliers must be balanced, as they contribute significantly to producing high-performance materials essential for modern industrial applications. By acknowledging and optimizing these components, industries can continue to advance and thrive in an ever-evolving landscape.

Tech Hub Digital, a one-stop destination for complete technology-related information.